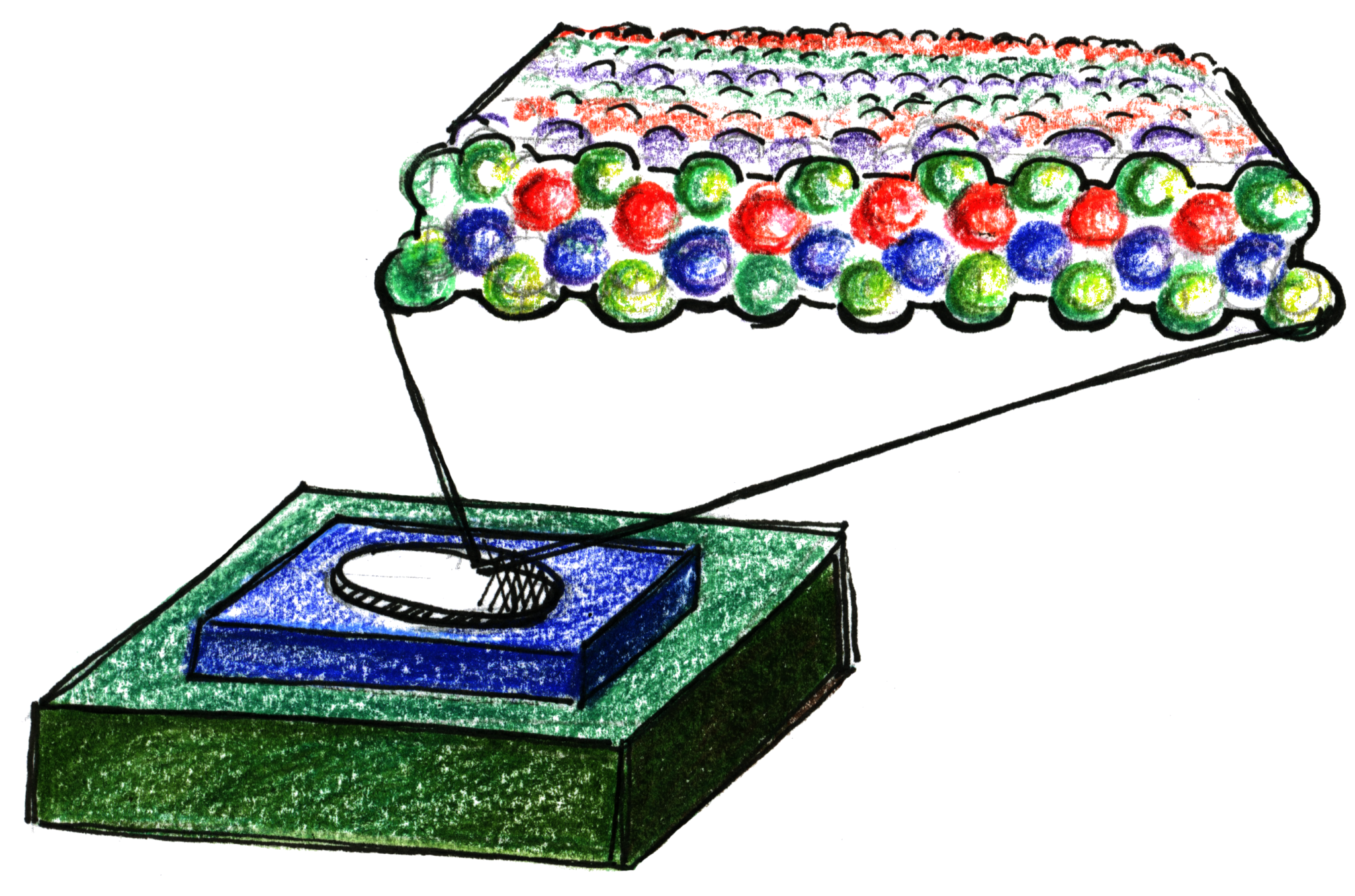

Researchers at the School of Engineering & Applied Science have just successfully imprinted the structures of surfaces at the atomic level.

The breakthrough allows for surfaces that exhibit specific desired properties to be replicated — including surfaces with extremely high or low adhesion, ones that suit catalysts or enhance data storage and ones that have hydrophobic or hydrophilic properties. Published in the journal Communications Physics on Nov. 5, the study also uncovered some of the mysterious properties of metallic glass, which typically make it difficult to see where atoms are present in the material.

Under the direction of Udo Schwarz, department chair of mechanical engineering and materials science, the group explored the ultimate extent of detail that could be imprinted, challenging themselves to perform atomic imprinting to replicate atomic structures.

“The study was the first that showed that you could replicate, with metallic glasses, every little detail on an atomic surface,” Schwarz said, explaining that kinks and holes could be exactly reproduced.

First, the research team determined the optimal temperature to heat the glass material, the maximum pressure needed to press it and the material to be used as a mold.

Schwarz collaborated with mechanical engineering and materials science professor Jan Schroers, who studies a material class called bulk metallic glasses. Bulk metallic glasses are metal alloys, similar in strength to regular metals. But when heated above a specific temperature, bulk metallic glasses act like normal glasses, serving as ideal molding and imprinting materials.

“The purpose was to show that you can replicate atomic structures, as long as you have the mold,” Schwarz said. “We were looking for a substrate that showed lots of detail on it with the goal to replicate all of that detail.”

The researchers found that strontium titanate made the most effective molds, above materials such as graphite, sodium chloride and silicon. Strontium titanate was able to capture all the structures of the surfaces during the imprinting process, creating exact replicas. In addition, strontium titanate does not transfer its atoms to metal, so no atoms from the mold stuck to the metallic glass.

By creating these metallic glass-imprinted replicas, the team confirmed that these surface structures could be copied to the atomic level, Schwarz said. Previous atomic imprinting studies were not able to replicate the structures to that level of detail.

According to Zheng Chen SEAS ’20, a co-author of the study, the research demonstrated that the metallic glass could be molded with specificity down to atomic size, but no further.

“We can imprint the structure of a crystalline material to the atomic level … To me, this is the first piece of evidence to show that the atoms’ sizes are the smallest size limit of [the] replicating of bulk metallic glasses,” he said.

Katherine Du | katherine.du@yale.edu .