Courtesy of Yale School of Engineering and Applied Science

Train cars in Connecticut may be modified for safer travel during the COVID-19 pandemic, thanks to the work of two Yale undergraduate students in the Department of Chemical & Environmental Engineering.

After their summer plans were cancelled, Marley Macarewich ’22 and Nathan Pharr ’22 turned to the SEAS 2020 Summer Design/Research Scholars Program, created by Deputy Dean Vincent Wilczynski, for virtual research opportunities. In partnership with the Connecticut Department of Transportation, Macarewich and Pharr worked on an eight week long project in which they researched ways to reduce the spread of COVID-19 in railcars. They also developed criteria and design features to inform decisions regarding the purchase of a fleet of new railcars by the CT-DOT.

“We were paired with the DOT to work on a project to redesign railcars that would mitigate the risk of spreading COVID-19,” Pharr said. “The way we did this was looking at current railcars and what could be changed or fixed to address this problem, and then looking at more long term solutions and ways that new railcars could be introduced.”

Macarewich and Pharr initially spent two to three weeks conducting a detailed literature review and speaking with Yale professors, as well as other local universities, to gather background information on virus transmission and air filtration systems in trains.

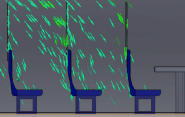

The group looked into the three primary modes of virus transmission — droplets, aerosols and infected fomites, but their initial research was not very rewarding.

“The biggest challenge would be how little information there is out there,” Macarewich said. “If you Google COVID-19 in railcars, very surface level stuff will come out, but there’s not a lot of deep information you could make informative decisions about.”

This was not the only hurdle the pair faced. Pharr also noted that the problem they were addressing is very complex. Both Macrewich and Pharr said that the rapidly developing information on COVID-19 made it difficult to effectively propose solutions.

According to Macarewich, however, some solutions that the pair suggested were surprisingly simple. For example, restricting the standing area around air intake vents could prevent particles that a passenger exhales from circulating throughout the cabin.

Still, overall, tackling the problem was not as easy as Macarewich and Pharr originally believed.

“Initially we thought we could just change the filtration system and everything would be perfectly fine,” he said. “But realizing how these train cars that are tons of years old, don’t really have the technology or equipment to support some of the recent filters we have now, we really had to look into different solutions that could be approached to the current trains.”

These challenges led Macarewich and Pharr to employ a combination of engineering and non-engineering measures — such incorporating a personal, passenger-individual ventilation system and evaluating cleaning protocols — to develop solutions.

They also considered passengers’ comfort and experience taking the train. For example, although leaving train windows open is the easiest method of increasing outdoor airflow and filtering out potentially infectious particles, according to Pharr, this could result in the constant inflow of cold air, which could make the passengers’ experience less pleasant. This is especially true for the many passengers with longer commutes of 45 minutes to two hours.

“It’s interesting focusing on the main component at hand, being the virus, but also having to take into account everything else in terms of publicity, the passenger convenience and comfort and all these things,” Pharr said.

The pair of researchers met virtually with the CT-DOT three times over the summer to discuss proposed solutions and obtained the blueprints to railcars of trains in Connecticut to aid with their research.

Macarewich and Pharr synthesized their findings into a 40 page report. Proposed solutions outlined in the report include a universal mask requirement, potential seating charts designed in accordance with social distancing guidelines, the creation of a separate car for high-risk individuals, increased outdoor airflow, the use of non-porous, smooth materials for seat covers and train surfaces and the implementation of plexiglass shields between seats.

According to Assistant Dean for Science & Engineering Sarah Miller, who mentored the pair on the project, Macarewich and Pharr’s final report was regarded by the CT-DOT as “extraordinary.”

“For my part, working with Marley and Nathan was a summer highlight for me,” Miller wrote in an email to the News. “This team modeled the kind of collaboration skills the best engineers are known for. Through diligence, a willingness to pursue hard questions, and lots of reading, they became fast experts in COVID transmission.”

Macarewich and Pharr are now working with Krystal Pollit, assistant professor of epidemiology, to prepare a manuscript of their summer research to be published in a peer-reviewed journal.

They say that they hope to apply the skills they gained over the summer to their new research ventures. Macarewich is working in Associate Professor of Chemical & Environmental Engineering Drew Gentner’s Lab, and Pharr hopes to work at the School of Architecture in the near future.

“Being able to have a job that was impactful, even remote, during the pandemic was a really incredible experience to have and just gaining so much knowledge in terms of research…as well as the niche topic of aerosols and railcars,” Pharr said. “We kind of took our skills that we learned in this project and have moved them over to new areas.”

According to Macarewich, train ridership in Connecticut is down by 95 percent due to the pandemic, as of early July.

Maya Geradi | maya.geradi@yale.edu